Do you have a requirement to measure dust at your facility or on a work site? Here is some background information to help get you started.

What is dust or particulate matter (PM)?

Dust is a generic term used to describe fine particles that are suspended in the atmosphere. It covers all airborne pollutants that are not gaseous. PM pollution consists of materials (including dust, smoke and soot) that are directly emitted into the air or result from the transformation of gaseous pollutants. Some common dust or PM sources include: Soil | Vegetation | Sea Salt | Fossil Fuel Combustion | Burning of Biomass | Industrial Activities

Classification of dust

Three useful definitions:

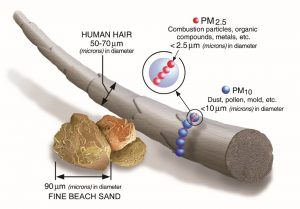

Total Suspended Particles (TSP) typically refers to particles 50um in size or less

PM10 refers to particles that are 10µm in size or less

PM2.5 refers to particles that are 2.5µm in size or less

Particle size and human impact

Particle size is important from a human impact perspective. The smaller the particles, the deeper they can penetrate into your body. Particles greater than 10 µm are trapped in the nose and throat. Particles less than 5µm can make their way into the bronchial tubes. Particles of 2.5µm or less will get into the deepest part of the lungs. So, if you consider silica dust for example, where particle sizes range from 0.1µm to 100µm in diameter, there are certainly health considerations.

Dust measuring methods

When considering Dust measurement methods, there are two main categories of monitors – Compliance Monitors and Dust Management Monitors. Compliance Monitoring is conducted in accordance with the relevant Australian Standards. Dust Management Monitors, such as particle counters, are not compliant with standard methods, but are used widely for on-site dust management. These have proven to be low cost, fast response instruments that are ideal for indicative monitoring.

Summary dust measurement methods

Dust Monitor

Description / How it Works

Compliance / Dust Management Monitor

Images

TEOM – Tapered Element Oscillating Microbalance

Particles in air stream collect on filter mounted at top of oscillating tapered glass tube fixed at its base.

As weight of filter increases, oscillation frequency decreases.

Change in frequency translated into particle mass

Compliance and management

High Volume Sampler

A constant flow rate of ambient air is drawn through a filter paper. The mass of the collected particles is determined by weighing the sample filter before and after sampling in a temperature and humidity-controlled environment. Particle concentration is calculated using the mass of sample collected and total volume of air drawn.

Compliance

BAM – Beta Attenuation Monitor

The BAM is a continuous monitoring method and operates by drawing air through a continuous glass or filter tape. Beta radiation emits low energy electrons that pass through the particles deposited on the tape and the attenuation of electrons is measured in a sensor located above the tape. The attenuation is converted to an estimate of mass based on the absorption coefficient.

Compliance and management

Particle Counter

Particle counters use the principle of light scattering and measure the particle size distribution and number of particles to provide an estimate of particle mass. A narrow air stream is directed through a small sensing zone, where an intensive light beam illuminates it. Light is scattered by individual particles and sensed by a detector as an electrical pulse. Particle size is determined from the pulse amplitude and the particle number is determined from the number of pulses).

Management