Looking to do some deep sampling? Solinst offer some really neat solutions for this application.

Here are a couple of examples that provide a more in-depth look at two of the products listed in the summary table above:

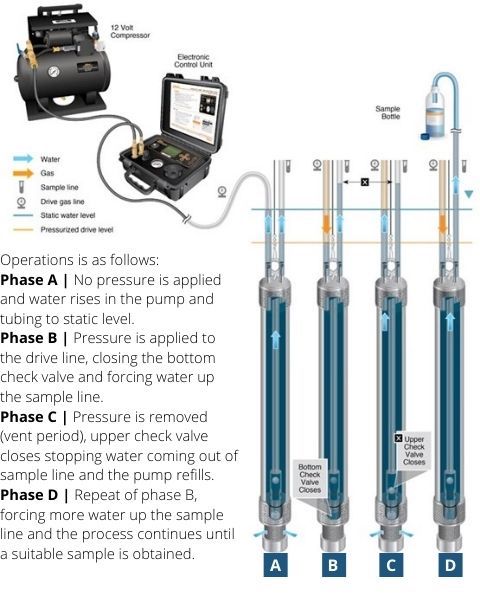

Double Valve Pumps

When considering Double Valve Pumps for deep sampling applications, it is good to understand how they operate. When a Double Valve Pump is submerged, hydrostatic pressure forces water through the filter intake in the base of the pump, filling the pump body and both the drive and sample lines to static level. So, the pressure needed to take a sample is calculated based on the depth to static level (plus 10psi for line loss). In a good example of this, HydroTerra has used the Solinst Model 408 1.66″ diameter Double Valve Pump to depths of 1200m. Special weights were designed to fit on the bottom of the pumps to counteract buoyancy. It is also recommended to use dedicated pumps at this depth, to save time, obtain representative and repeatable samples and to eliminate the need for decontamination between sampling rounds.

Model 425-D Deep Discrete Interval Sampler

The Model 425-D Deep Discrete Interval Sampler allows samples to be taken from distinct levels in a well, borehole, or surface water body. Weights are added to the Discrete Interval Sampler before lowering to overcome buoyancy at greater depths.

The Discrete Interval Sampler operates on the basic principles of hydraulics. Once the Sampler reaches the desired sampling depth (Stage 2 – Deploy), it is pressurized (Stage 3 – Pressurize). The pressure acts on the top of the internal piston (large surface area) overcoming the hydrostatic pressure acting on the bottom of the piston (small surface area) pushing the Sample Release Valve open, allowing sample water to fill the Sampler body. As the Piston assembly moves to open the Sample Release Valve, it also moves the Pressure Retainer away from a small o-ring sealed opening in the bottom of the Pressure Chamber, allowing the air to vent through the Vyon Filter on the exterior of the Sampler, while the Sampler fills with water.

After the sample is collected, the pressure is released from the Sampler, causing the Piston Rod to retract, sealing the Sample Release Valve and vent hole (Stage 4 – Vent & Remove). The sealed Sampler is then retrieved to surface, maintaining chemical stability of the sample. At surface, the sample is collected by reapplying pressure to the Discrete Interval Sampler to open the Sample Release Valve (Stage 5 Pressurize and Empty).